About us

Fogutek AB was founded in 1985 by Björn Lundstedt. Today the company is owned and run by his daughter Ingela Lundstedt. Fogutek is a contract manufacturer of products made from technical rubber. With our expertise in materials and production technologies, we work with the customer to develop and produce specialized products meeting high quality standards.

We will continue to develop and to be a part of the future progress towards sustainable materials and production methods. To achieve this we will be an integral part of our customers' R&D departments and continue to have close collaboration with the suppliers of raw materials who hold expertise in their particular niches.

Rubber

We work with most polymer types. We select the right material for the right product.

Polymertyper:

- FKM – Fluorocarbon rubber, e.g.: Viton ®

- FFKM – Perfluoro rubber

- NBR – Nitrile rubber

- HNBR – hydrogenated nitrile rubber, Including: Therban ® Zetpol ®

- EPDM – Ethylene Propylene rubber

- Q - Silicone Rubber, Including: Elastosil ®

- CR - Chloroprene rubber

- SBR – Styrene rubber

- NR – Natural Rubber

- ECO – Epichlorohydrin rubber

- PUR – Polyurethane rubber

We optimize and extend the properties of the polymer types through the development of unique recipes for detectability, friction, temperature, chemical resistance, and electrical conductivity.

Innovation & Development

We offer consulting services for the development of new rubber materials, products, and design. The assignments we take on should be transparent, in which we will share our experiences undcondionally. This is of course accompanied with a non-disclosure agreement.

Previous assignments:

Polymer development: We guide you through, using independent testing, to evaluate the processability and the properties of an all-new polymer.

Software testing: New raw material properties as compared to a pre-existing compounds on behalf of a supplier of raw materials.

Development: Detectable material for food and medicine applications.

Design: New products for specific applications.

Business policy

Fogutek manufactures custom-made molded components from advanced rubber material. Those who set the highest standards of quality and environmental requirements are ourselves. We are constantly working on improving and developing our management systems and production processes so that we comply with the requirements of authorities and our clients.

We will continue to be the partner of choice for those who put the most value in: The highest product- and production quality, sustainable products, the best support, service and delivery, thought-out work environment, which is conducive to a dedicated staff, as well as the cost-efficient of production.

Sustainability

We aim for our production facilities to be as energy efficient and productive as possible. When purchasing new equipment, we take into account their environmenta performance, energy consumption and production capacity. For the development of our own rubber compounds, we look for better environmental choices in the purchase of raw materials and chemicals, when this is technically and economically feasible.

With projects, we guide our clients in selecting the most suitable materials in terms of environmental impact and durability. With planned purchases, we reduce the number of shipments, and control the transports themselves, to the extent that it is possible to co-ordinate. We comply with the requirements of the legislation. We have an excellent emergency preparedness by working systematically with the assessment of the risks involved. Through the ongoing work on the evaluation of our impact on the environment, we strive to continually improve our environmental performance.

Lab

Vi har vårt eget laboratorium och genom långvarigt samarbete med andra lab har vi tillgång till avancerad mätanalys och provutrustning. Detta betyder att vi kan dokumentera prestandan på våra kunders produkter. De kvalitetskrav som tillämpas på företaget uppfyller kraven i ISO 9001-2015.

We tailor each and every assignment to suit your needs

Blasting

We have glass, plastics, and air blasts. We are carry out blasting according to the customer's requirements. (We do, however, have limitations in terms of size of the blast furnace).

Tumbling

We carry out tumble finishing. We carry out the tumbling according to the customer's requirements.

Material

Fogutek mainly manufactures precision details of high-quality materials, e.g.:

- FPM – Fluorocarbon rubber

- HNBR – Hydrogenated Nitrile rubber

- NBR – Nitrile rubber

- EPDM – Ethylene Propylene rubber

- Q – Silicone rubber

- FMQ – Fluorosilicone rubber

We are constantly developing new rubber compounds. This happens on our mixing deparment, where we have a large number of recipes that meet specific requirements.

Clean Room

For the production of particularly sensitive products, such as rubber provided to the medical industry, and components for food-grade applications, we manufacture in a separate specially-adapted department.

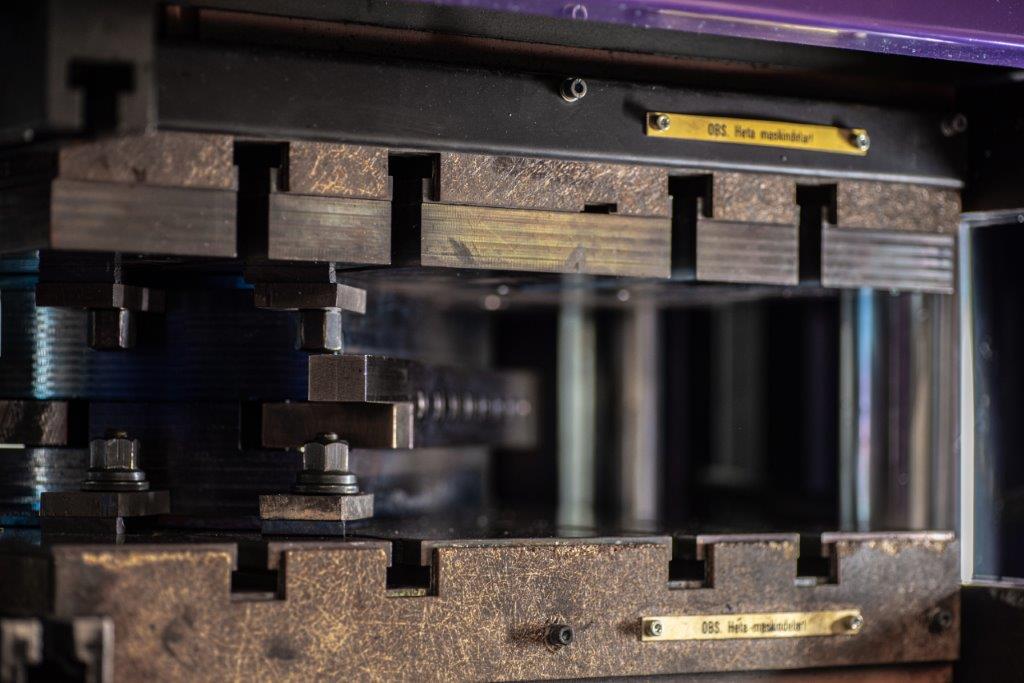

Equipment

Our production equipment meets the high standards of accuracy and safety. The machine park is constantly renewed in order to maintain a high level of manufacturing engineering.